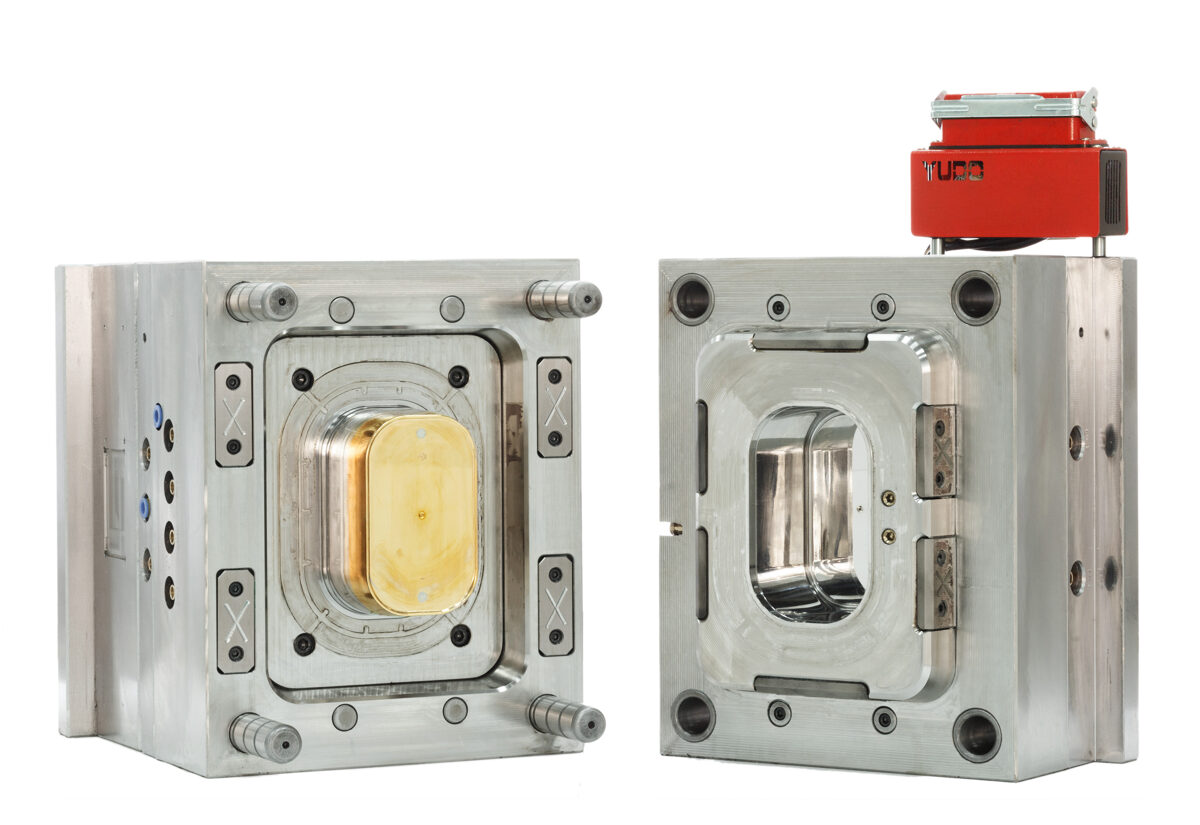

To start the production of plastic products, you need a mould!

To get your quote for plastic products please check which of the two main options below applies to you:

2) You have no mould and you are starting from scratch:

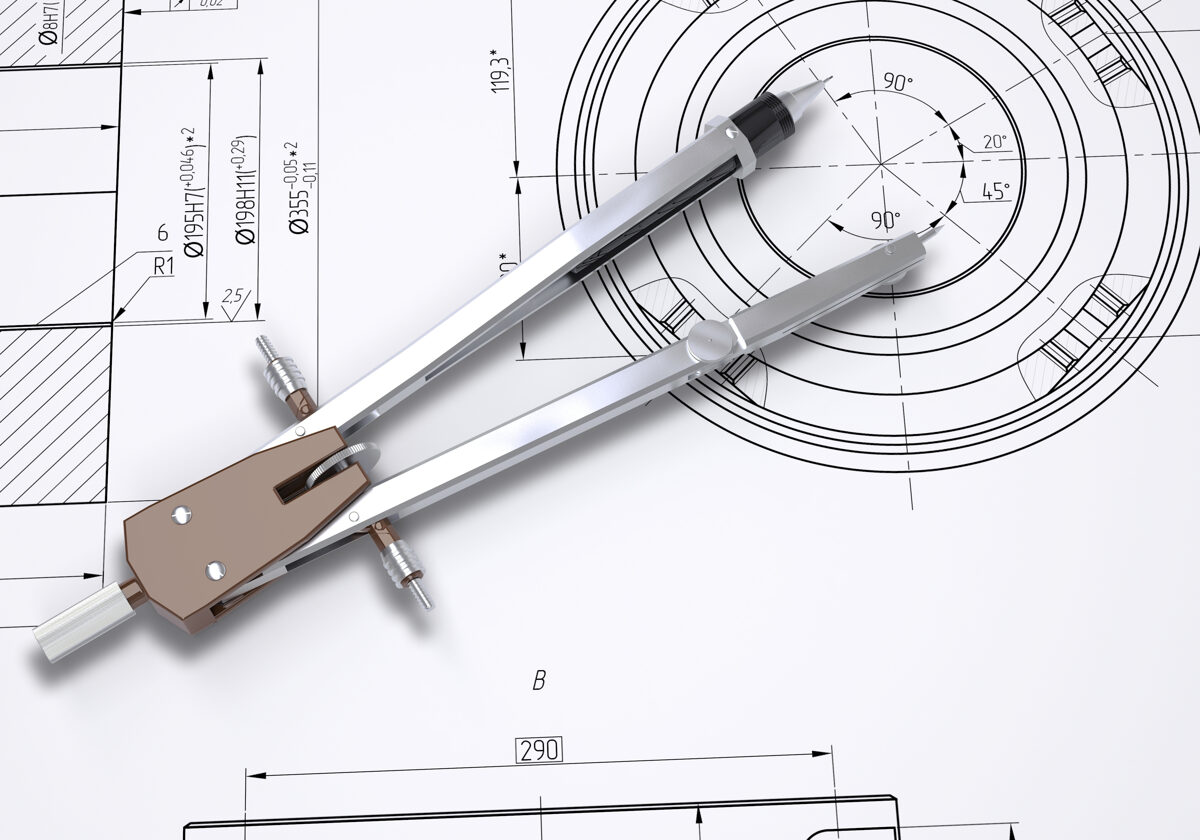

2.1) You already have a 3D model of the product, drawings, plastic specification, scheduled capacity per month/year and other product documentation. In this case, we can quickly offer you the most accurate quote for both the product and the mould.

2.2) You have a sample to copy or modify.

Here, the accuracy of the quote depends on how much information you can provide: minimal accuracy if you send us a photo, and a more accurate quote if you can send us a sample. If possible, please provide information about unit weight, dimensions, type of plastic, consumption per month/year, additives (UV stabilizers, dyes, antioxidants, flame retardants etc.). All this information will speed up the estimation process and we’ll be able to send you a more accurate quote.

2.3) You only have an idea and sketches of the required product.

This is the longest process with lower estimation accuracy. The reason is that the price of a product can only be calculated with an approved final drawing, and at the idea stage the quote cannot be accurate. In some cases, we can offer assistance in development of a product. This service requires prior approval and it isn't free: the average cost of one unit is 150 euros*. (*design development of a product comes only with a contract for ordering a mould, i.e. this work is a part of the project).

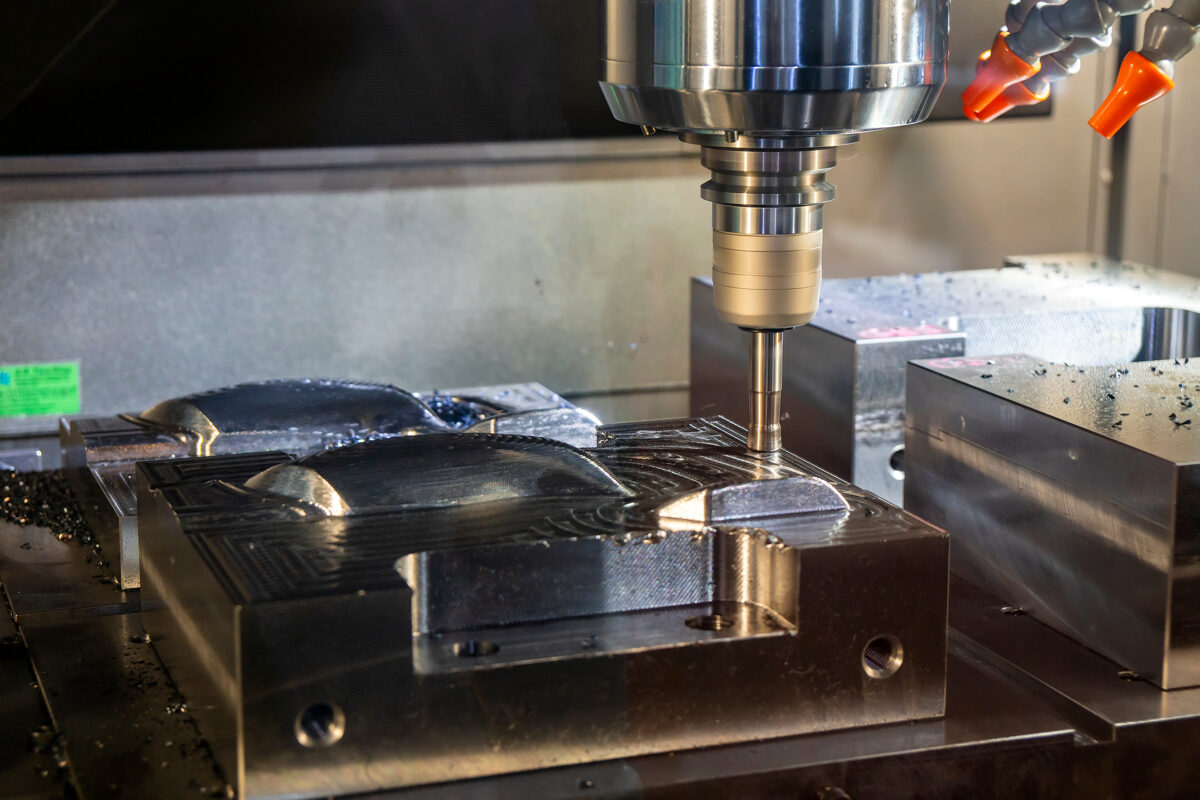

Our job is to produce plastic parts, but for the convenience of our customers, we can also provide moulds.

However, if you order moulds yourself and you have no experience in this, please bear in mind that the final cost of the product depends on the performance and quality of the mould. If the mould turns out to be considerably slower than scheduled, the price of the production service will increase. As well, warranty or post-warranty events shall be paid for by the owner of the mould. If you order a mould from us, we do not change the approved price of the production service once the project has been launched, and we provide timely service of the mould for the entire period of its operation.